In this guide

Which system is right for your business – enterprise resource planning (ERP) or material requirements planning (MRP)? It all comes down to what your organisation needs. MRP focuses solely on optimising manufacturing processes and ERP can help streamline and automate processes across your business.

This guide compares the two systems to help you decide which is right for you.

What is an ERP system?

An ERP system is software that lets you use a single database to plan, manage and automate the business processes across your organisation.

How do enterprise resource planning systems work?

Enterprise resource planning systems work by bringing together data from different business functions and updating a common database.

For example, MYOB Acumatica is a cloud ERP system with features that offer the general business functionality of:

What types of businesses use ERP systems?

Businesses from almost every industry use ERP software to bring their business data together, automate processes and get real-time reporting. Some ERP systems support industry-specific requirements.

For example, MYOB Acumatica also offers tailored solutions for the following industries:

What is an MRP system?

An MRP system is software you’ll use to plan the materials and components needed at different stages of the manufacturing process. This involves analysing your materials and components on hand and estimating what you need more of and when.

How do materials requirements planning systems work?

MRP systems work to help reduce downtime and increase productivity. They can help with:

Production planning and scheduling

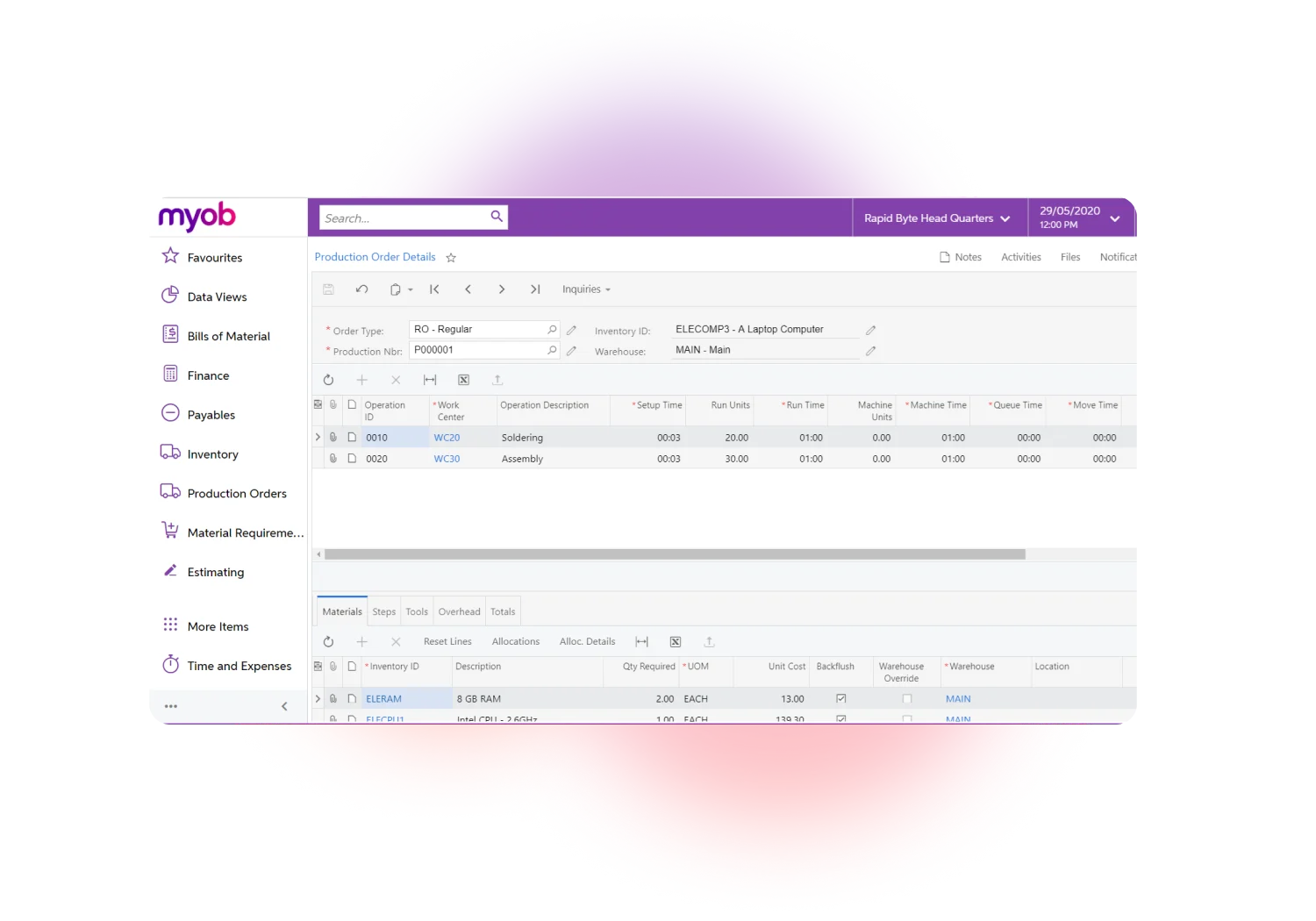

Tip: MYOB Acumatica Manufacturing has features that include MRP, production management, bill of materials and routing, product configuration and estimating. Contact us to arrange a demo.

Discover how medical device manufacturer PolyNovo implemented MYOB Acumatica Manufacturing to streamline processes and save time and money. In doing so, they saved an estimated $48,000 per annum!

What types of businesses use MRP systems?

Different types of manufacturing businesses use MRP systems to order and plan production materials.

Advantages of ERP systems

The advantages of ERP systems are wide-ranging and include:

Increased productivity with process automation

Increased productivity is one of the many benefits of process automation. ERP systems can complete tasks faster and more accurately than people can. For example, an ERP can automate invoicing, financial reporting, stock level monitoring, demand forecasting, rostering, payroll processing and more. This frees your teams from admin work to focus on projects that add more value to your business.

Faster decision-making with real-time visibility

ERP systems enable faster, better decisions with real-time visibility across your organisation. They also improve efficiency by eliminating the time and effort needed to find accurate data. Your teams can get on with their work faster, respond to new opportunities as they arise and provide a better customer experience.

Tip: MYOB Acumatica has in-built reporting and business intelligence tools to deliver deeper insights.

With a range of reports, dashboards and business intelligence tools, you can analyse trends, customer insights, product turnover and more. For even more detailed reporting, you can integrate BI software from our App Marketplace.

One centralised location for all data

ERP systems provide one centralised location for all data across your business. Therefore, you don’t need to jump between spreadsheets and other software applications to get the complete picture. An ERP gives you one source of truth for business data, so you don’t run into duplication issues or errors in your reporting or analytics.

Enhanced data security and compliance

A cloud ERP system has advanced security features built-in, along with permission controls so employees only see the information they need. You can also enforce a segregation of duties between employees to reduce the risk of fraud.

Advantages of MRP systems

For manufacturers, there are many advantages of using MRP software. You can expect an MRP system to deliver:

Cost savings by streamlining manufacturing processes

By streamlining manufacturing processes with an MRP system, your business can benefit from many cost savings. An MRP collects and processes data to help make manufacturing processes more consistent. It also helps you identify and resolve any inefficiencies or bottlenecks. This insight may help you improve production efficiency, save money and improve overall supply chain management.

Robust inventory control and lower inventory costs

Drawing on aggregated inventory data, MRPs monitor stock and replenishment levels. They can also automatically initiate the re-ordering process. This ensures you have the right materials available at the right time. You also get valuable insights into inventory turnover, supplier performance and lead times. This data can help you reduce carrying costs, minimise stockouts and facilitate better demand forecasting.

Fewer production delays

Manufacturers using MRP software are likely to experience fewer production delays. MRPs are particularly valuable for orders involving multiple sub-assemblies. The system gives you increased visibility over the components needed at each sub-assembly and the time required at each step. This can help you avoid miscalculating timings and keep production flowing smoothly.

Better traceability through supply chains

Better traceability through supply chains is another reason manufacturers choose MRP systems. When every step in the supply chain leaves a trail that you can track, it’s easier to monitor quality control.

Improved customer satisfaction

Anything you can do to improve customer satisfaction is a big win. Implementing an MRP system can be a great supply chain and inventory management tool. The better you can do those two things, the more confidence your customers will have that you can deliver on time, every time.

How to decide which system is right for your business

So, how do you decide which system is right for your business? If you’re tossing up between an ERP and an MRP system, here are some factors to consider:

Which business processes do you want to improve?

Start by considering which business processes you want to improve. If you’re a manufacturing company that wants to improve your production processes, an MRP system has the features you need. However, if you want to automate a variety of business functions beyond MRP, ERP systems have a much broader scope.

Tip: Use MYOB Acumatica’s manufacturing software to get the best of both worlds.

A full ERP system, MYOB Acumatica's manufacturing features include in-built MRP functionality. Data flows in from across your business to power your MRP with comprehensive and real-time data. This gives you a clear and accurate view of your supply and demand, dramatically improving the accuracy of materials planning.

What is your budget?

Your budget comes into play, too. Generally, MRP systems are more straightforward to build, which means they’re less costly to implement. However, an ERP system can lead to better efficiency and productivity across your business. Therefore, the return on investment can be far greater.

What stage is your business at?

If your business is at a stage of rapid expansion, an ERP system provides the automation you need to keep up with and sustain that growth. MRP systems may be better suited to smaller manufacturers seeking consistency and standardisation.

ERP vs MRP FAQs

What is the relationship between an MRP and an ERP system?

An MRP can be a subset of an ERP. While both can work as standalone systems, when integrated, an MRP supplies information about manufacturing materials and components that an ERP uses to inform other business functions. For example, a finance department can use MRP data to calculate the cost of goods sold and determine how to price a product.

What are the drawbacks of MRP systems?

The biggest drawback of MRP systems is the time involved in ensuring data accuracy. Data must be entered into your MRP system at scheduled intervals, which can lead to incorrect information or delays in decision making. An MRP feature within a cloud ERP can all but eliminate this issue as an integrated ERP updates in real-time.

What are the challenges with ERP systems?

The most significant challenges with ERP systems are cost and complexity. That’s why it’s important to carefully evaluate the potential ERP benefits for your business. Look for an experienced vendor with an implementation team who can guide you through the ERP implementation process.

Are MRP systems expensive to implement?

Generally, MRP systems are less expensive to implement than ERPs because the software isn’t as complex. However, if you want to streamline and automate processes beyond the shop floor, you’ll need to implement additional software.

ERP vs MRP – why not both?

MYOB Acumatica's manufacturing features include built-in MRP functionality, so your materials planning is always working with real-time, accurate data. The cloud ERP does more than that though, powering your organisation’s efficiency, profitability and growth across the board. MYOB Acumatica automates repetitive tasks, connects data in real-time and delivers the insights you need to take your business to the next level.

Find out more and arrange a demo today.

Disclaimer: Information provided in this article is of a general nature and does not consider your personal situation. It does not constitute legal, financial, or other professional advice and should not be relied upon as a statement of law, policy or advice. You should consider whether this information is appropriate to your needs and, if necessary, seek independent advice. This information is only accurate at the time of publication. Although every effort has been made to verify the accuracy of the information contained on this webpage, MYOB disclaims, to the extent permitted by law, all liability for the information contained on this webpage or any loss or damage suffered by any person directly or indirectly through relying on this information.

Contributors

MYOB Subject Matter Experts