In this guide

To create a bill of materials (BOM) for one of your products sounds simple — list the name, number and quantity of each material or component that goes into it. However, an accurate BOM can be the difference between a booming business and one that struggles to show a profit.

In this guide, you'll learn about the different kinds of BOMs, their benefits, and the steps to creating your own.

What is a bill of materials?

A bill of materials lists all the materials and parts you need to construct, manufacture, or repair your product or service. It should itemise sub-assemblies, intermediate assemblies, and sub-components, where you need to complete a process or create a component before you can start on the main project.

Why should you use a bill of materials?

You should use a bill of materials to help you plan how much material to buy, estimate costs, and control your stock levels. This will help you keep control and oversight of operations, boosting efficiency while minimising waste, delays and costs. Your BOM should also help you find the causes of and resolutions for any product failures.

Types of bills of materials

The types of bills of materials include engineering BOM, manufacturing BOM and sales BOM, amongst others:

Engineering bill of materials (EBOM)

An engineering bill of materials (EBOM) is used to design a product rather than manufacture it. It ensures that the final product will meet all specifications and requirements.

Manufacturing bill of materials (MBOM)

A manufacturing bill of materials (MBOM) turns these engineering designs into a manufacturing task list. It acts as the source of truth, from how to build the product to what components or materials you'll need and when.

Sales bill of materials (SBOM)

A sales bill of materials (SBOM) is similar to a manufacturing bill of materials (BOM), but it is specifically used during the sales process. It is typically used for made-to-order or customised products. The SBOM provides detailed information about the components of a product before assembly, giving both you and your customer a clear understanding of what the final product will include.

Bill of materials structures

Bill of materials structures can be single or multi-level. They typically follow a hierarchy, with the finished product at the top and parts or materials underneath.

Single-level BOM

Single-level BOMs are used when a process is relatively simple, with no lower-level sub-assemblies required. For example, say you produce muesli bars with ready-to-use ingredients – you don't need to pre-roast the nuts or turn bulk chocolate blocks into drops, for example.

Multi-level BOM

A multi-level BOM is used when your process includes sub-assemblies, which means you must process items, components or ingredients before creating the final product. Say you plan to make a more complex muesli bar with yoghurt-covered nut clusters on top, for example. In this case, your multi-level BOM will show what needs to happen to create the yoghurt clusters before you can produce the bars themselves.

What should be included in a bill of materials?

Here's what should be included in a bill of materials:

The name of what you're making or doing

The raw materials and how much of each you'll need, including any sub-assembly processes

Part numbers with names, descriptions, unit costs and quantities — including any for sub-assemblies

How to create and manage a bill of materials

To create and manage a bill of materials, follow these steps:

Determine your product

Determining your product is the first step — get clear on what you're making and how you'll identify it in your inventory. At this point, you should note any variations – say you're making two versions of the same muesli bar, one covered in chocolate drops and one with yoghurt nut clusters. Your product BOM would list the materials needed to make the base bar, and you'd have BOMs for each variation.

Formulate a list of components

Next, formulate a list of components. This should include the raw ingredients you'll need and any sub-assemblies. You should also note anything that will be helpful to those doing the assembly.

Specify quantities for each component

Specifying quantities for each component will help ensure you have the right amount of stock on hand. At this point, you'll also decide if you want to see a batch view or a per-item view of your BOM. A batch view makes sense for items like muesli bars, whereas a per-item view is more appropriate for assembling custom kitchen cabinetry.

These figures can help with inventory management. You may also want to add 15% of safety stock to cover unexpected demand fluctuations or supply delays. Safety stock helps ensure that production or sales are not interrupted due to poor stock control.

Calculating costs for each component helps you understand the total cost of producing a batch or individual item. This calculation should include the costs of raw materials or components, as well as the expenses for assembly, labour, handling, and shipping.

Determine who has control over the BOM

Determine who has control over the BOM to keep your production process accurate and consistent. This is especially important when you expect changes or updates because it helps reduce the risk of errors. Typically, whoever designs the process or product will control the BOM, but other departments will need to access and contribute to it.

Review and refine regularly

Reviewing and refining your BOM regularly allows you to keep up with product or supply chain changes and developments or integrate new technological advancements.

Benefits of using a bill of materials

The benefits of using a bill of materials are varied. They can help you calculate economic order quantities, streamline the procurement process, and more accurately price your products.

Less wasted resources

Less wasted resources is a key benefit of a good BOM as it makes inventory management more accurate, minimising inventory days and inventory costs.

Simplified manufacturing processes

Simplifying your manufacturing processes reduces costs and time – a BOM helps achieve this by streamlining procurement, improving accuracy and enhancing production efficiency.

Improved efficiency

Improved efficiency is the natural outcome of a good BOM – you'll minimise lead times and order fulfilment times while maximising resource utilisation and profit margins.

Bill of materials templates

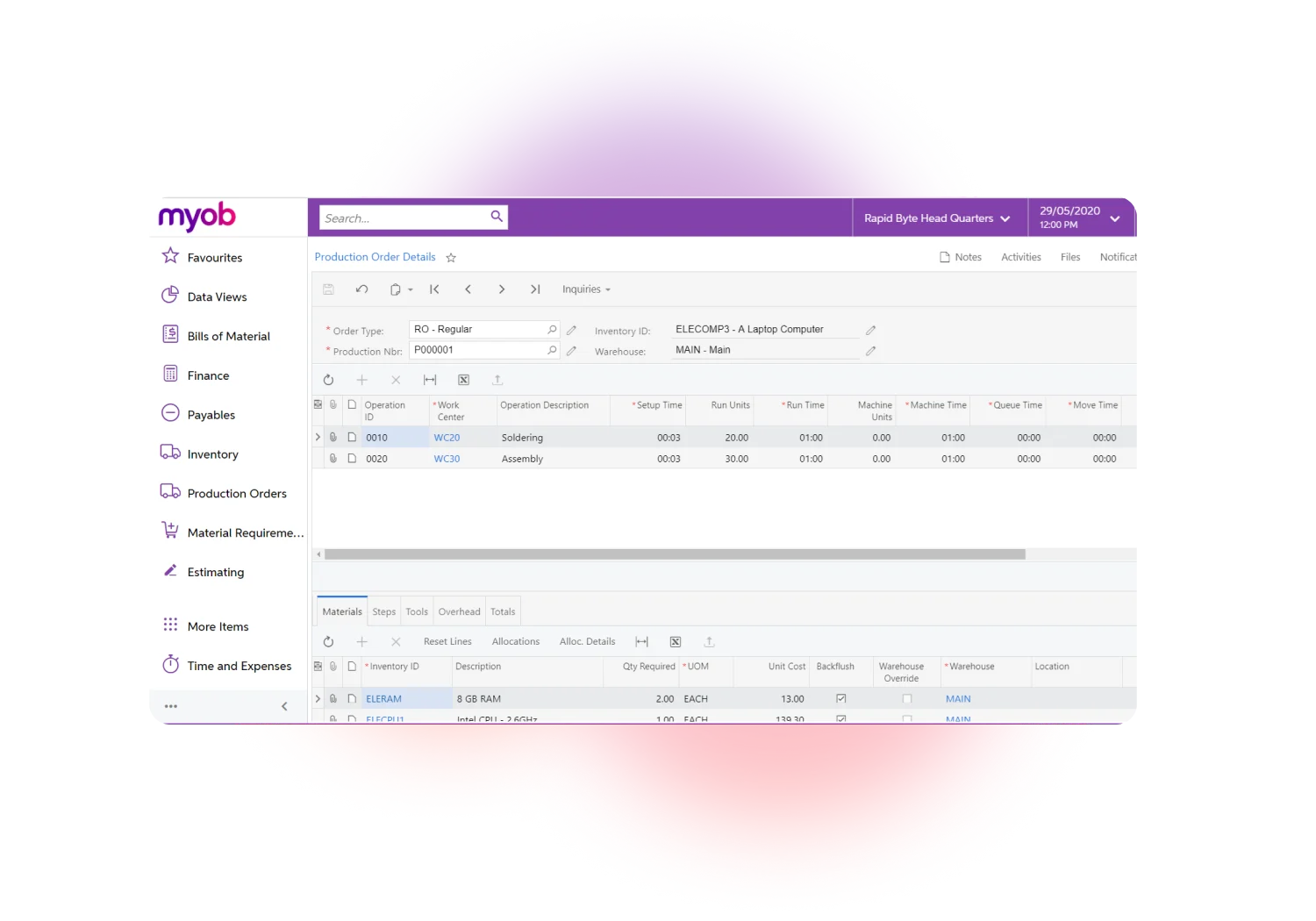

Bill of materials templates can help you get started, but manually managing your BOM can be time-consuming and error-prone. By contrast, the robust Bill of Materials features in MYOB CRM save time while simplifying order fulfilment.

For more complex manufacturing companies, MYOB Acumatica offers bill of materials, production management, material requirements planning, product configurator, estimating and more.

Bill of materials FAQs

What is the difference between a bill of materials (BOM) and a bill of quantities (BOQ)?

The difference between a bill of materials and a bill of quantities is that manufacturers generally use BOM to identify the materials and components needed for production, while the construction industry uses BOQ to estimate a project's cost.

The BOM itemises what is needed to manufacture an end product. In contrast, the BOQ provides detailed information on the materials, labour and costs involved in a construction project, helping to estimate and manage the project's financial requirements.

What costs are included in a bill of materials?

What costs to include in a bill of materials depends on your manufacturing process and what you're making. In general, you should include costs for raw materials, labour, purchased components and any other expenses, like the running costs of your facilities.

Who prepares a bill of materials?

Who prepares a bill of materials depends on each company and the item you're producing. However, you can expect people from departments of design, engineering, purchasing, manufacturing and more to contribute their expertise in most cases. Engineers will take the lead on engineering BOMs, and salespeople will have more input into a sales BOM.

What are the implications of a poorly managed BOM?

The main implications of a poorly managed BOM are squeezed or non-existent profit margins. These can be caused by stockouts, the risk of dead stock, increased carry costs from overstocking and production delays.

BOMs make a material difference

A bill of materials is the gold standard for manufacturers. It lets you clarify requirements so your team can work together to improve efficiency, minimise waste and maximise returns.

Small and medium-sized businesses can grow and scale upgrade with MYOB Acumatica.

Get in touch to demo MYOB Acumatica.

Disclaimer: Information provided in this article is of a general nature and does not consider your personal situation. It does not constitute legal, financial, or other professional advice and should not be relied upon as a statement of law, policy or advice. You should consider whether this information is appropriate to your needs and, if necessary, seek independent advice. This information is only accurate at the time of publication. Although every effort has been made to verify the accuracy of the information contained on this webpage, MYOB disclaims, to the extent permitted by law, all liability for the information contained on this webpage or any loss or damage suffered by any person directly or indirectly through relying on this information.

Contributors

MYOB Subject Matter Experts