Performing inventory reconciliation using these steps will help ensure your records are accurate so your customers get what they want when they want it. It’ll also help prevent items from sitting dormant on warehouse shelves.

What is inventory reconciliation?

Inventory reconciliation involves comparing the amount of stock on your shelves or stockrooms to the data in your point of sale or other inventory management system. This lets you see any discrepancies.

Why is inventory reconciliation important in business?

Inventory reconciliation is important in business because it helps you keep track of one of your biggest costs – your inventory. Checking your stock numbers helps to improve inventory forecasting and sales forecasting and minimises dead stock and stockouts. The goal is to minimise inventory costs, keep accurate accounting records and ensure you have the items your customers want.

Inventory reconciliation methods

Inventory reconciliation methods differ based on your business needs and inventory types. Here are the most common methods:

Seasonal reconciliation

With seasonal reconciliation, you check your inventory numbers before peak season. For example, if you sell sunscreen, a seasonal reconciliation will let you check that you have enough stock to meet the forecasted demand. Doing this each season will also help you analyse sales trends to optimise your stock levels.

Arbitrary reconciliation

Arbitrary inventory reconciliation involves checking outside of a fixed schedule or pattern. These checks could align with a quiet period to minimise disruption or be a spot-check if you suspect theft. This method is flexible and may mean you’ll discover discrepancies earlier.

ABC reconciliation

ABC reconciliation is when you categorise inventory into A, B or C groups based on its importance to your business. Category A items should have the tightest inventory control as this is your most profitable stock. Category B items will have less frequent checks, while category C items will be checked the least.

Steps to reconcile inventory

The key steps to reconciling your inventory are:

Select an inventory reconciliation method

Select an inventory reconciliation method that addresses your business needs. If it’s a fairly involved process for your company that’s likely to impact business as usual, you might opt for arbitrary reconciliation during quiet periods. If you have high-profit items mixed in with lower-value stock, ABC reconciliation might be of most value to you.

Count all your inventory

Count all your inventory by tallying how much of each item you have on the shelves or in the warehouse. You may want to organise by location, product type or category to simplify the inventory reconciliation process.

You can count your inventory manually or, depending on your stock and technology capabilities, may be able to use stock-keeping unit (SKU) barcode scanning to speed up the process.

Tip: Use inventory management software like MYOB to track what’s sold. MYOB uses transactions to maintain an inventory count, so you won’t need to perform stocktakes as often. With your inventory connected to your accounting software, your financials update in real-time. You have the data and insights to optimise your inventory and grow your business.

Compare physical inventory with records

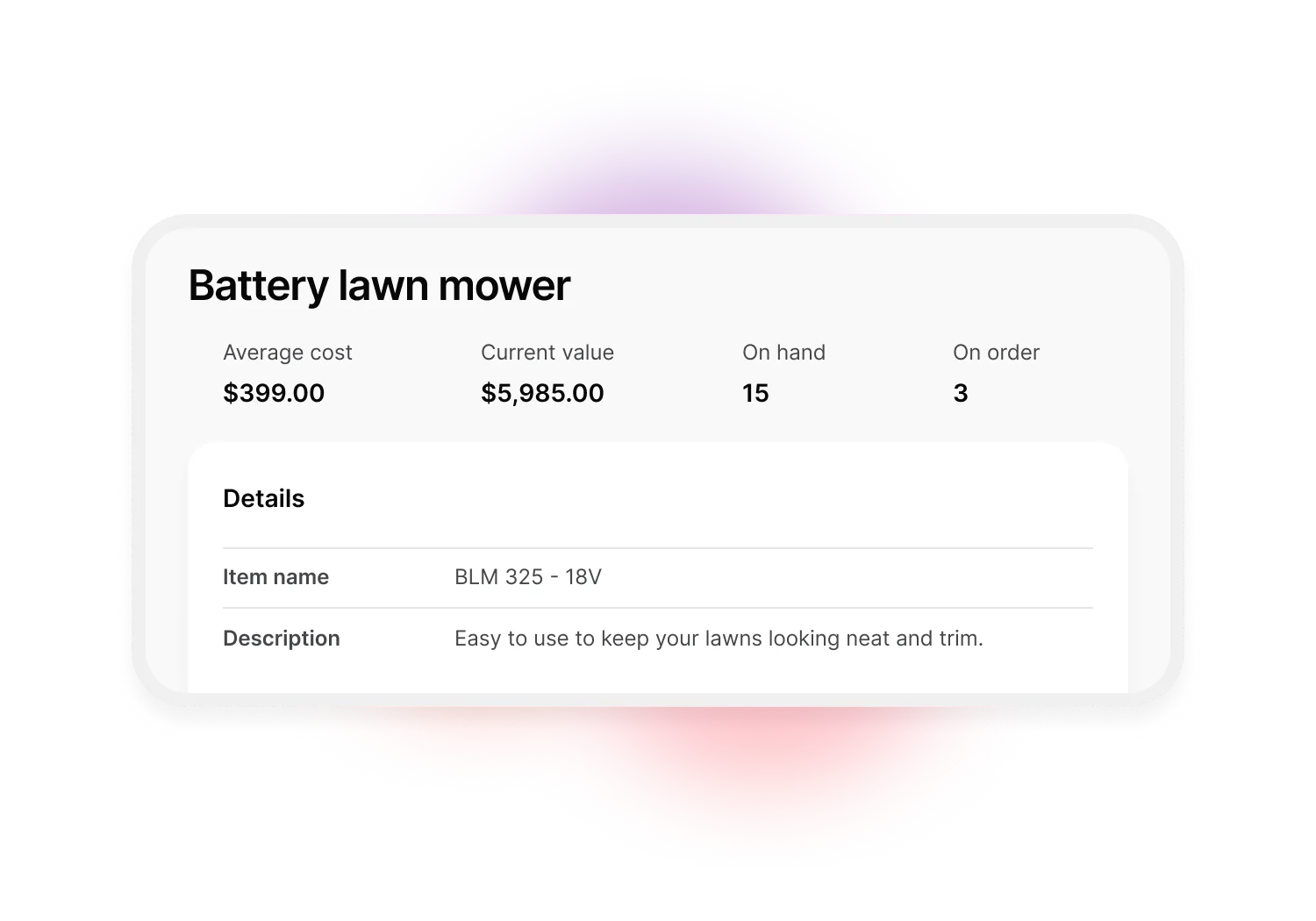

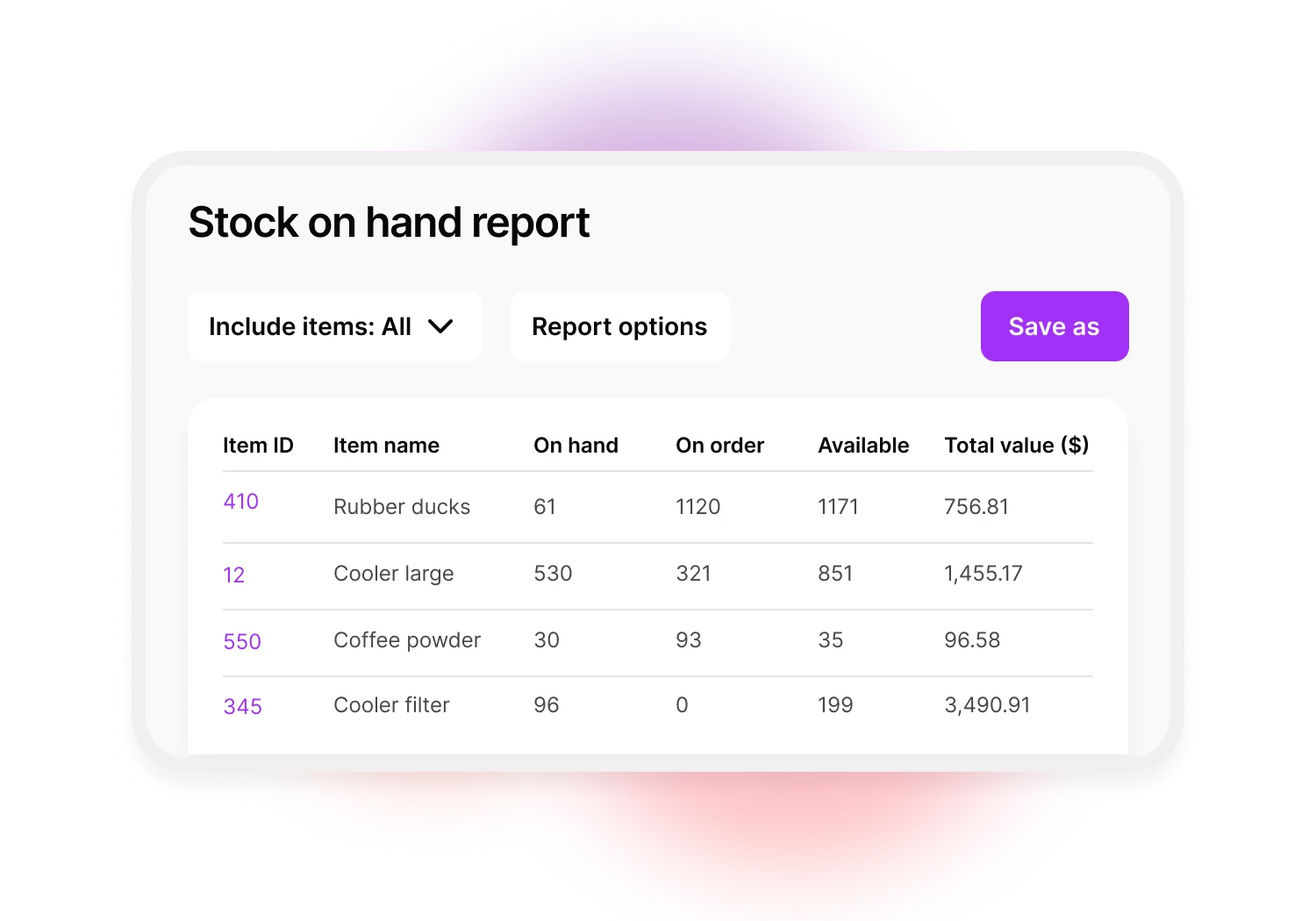

Compare the physical inventory count with your accounting records. This step is easy with inventory management software like MYOB, which generates instant stock-on-hand reports.

Identify discrepancies

Identify any discrepancies between your physical count and recorded inventory. Investigate the cause of the discrepancies and tweak processes to help prevent the issue from recurring.

Regularly perform inventory reconciliation

Regularly perform inventory reconciliations and ensure your employees are properly trained. If you’re set up with inventory management software like MYOB, you’ll only need to perform a manual count occasionally. Most of the time, you can rely on real-time perpetual inventory counts for the latest data.

Benefits of regular inventory reconciliation

The benefits of regular inventory reconciliation are wide-ranging:

Identify any theft or fraud

Identify theft or fraud faster by finding discrepancies between your inventory records and what’s on your shelves. Then, you can investigate and put in place measures to minimise the chance of it recurring.

Improve inventory management

Improved inventory management is a significant benefit of regular stocktakes. By better understanding true inventory levels, you can make sure you have the stock on hand to fulfil customer orders.

Tip: Use MYOB inventory management software to streamline and automate most tasks. You can even set up low-stock alerts and automatic stock replenishment.

Better demand forecasting

Better demand forecasting is another benefit of regular inventory reconciliation. It’s the information you need to make better reordering decisions, adjust stock levels, factor in supplier lead times and minimise the risk of over or under-ordering.

Up-to-date stock levels

Up-to-date stock levels are only possible with real-time inventory reconciliation. MYOB’s inventory management software gives you access to real-time figures without the hassle of frequent manual counts. Without real-time inventory reconciliation, you may lose sales when you run out of stock to fulfil an order.

Inventory reconciliation FAQs

What are the challenges of inventory reconciliation?

The main challenge of inventory reconciliation is counting the stock. People can make mistakes during the count, which can take a long time if your inventory is large or complex.

How often should you perform inventory reconciliation?

How often you should reconcile your inventory will depend on your business. Consider your inventory’s size, value, turnover rate and the likelihood of theft or errors. If you’re using inventory management software, you’ll need to perform manual counts less often.

How do you minimise inventory discrepancies?

The best way to minimise inventory discrepancies is through regular or real-time reconciliation. Inventory management software like MYOB automates your inventory controls, eliminating issues like human error.

Real-time reconciliation for accurate inventory data

Regular inventory reconciliation helps you understand your true inventory levels and stay on top of any costly discrepancies. Manual reconciliation can be time-consuming and error-prone.

MYOB Business and MYOB AccountRight have inventory management software built in. This gives you a real-time view of your inventory as it flows in and out of your business. It’ll help you track what’s in stock, automatically reorder your best-selling items, track profitability and stay on top of sales orders. Try it today!

Disclaimer: Information provided in this article is of a general nature and does not consider your personal situation. It does not constitute legal, financial, or other professional advice and should not be relied upon as a statement of law, policy or advice. You should consider whether this information is appropriate to your needs and, if necessary, seek independent advice. This information is only accurate at the time of publication. Although every effort has been made to verify the accuracy of the information contained on this webpage, MYOB disclaims, to the extent permitted by law, all liability for the information contained on this webpage or any loss or damage suffered by any person directly or indirectly through relying on this information.